I already wrote a little bit about the February challenge, but look for a full fledged post about it soon. I am just catching up with the January challenge. I am happy with my first effort with bias tape. It was interesting and a good learning experience, but I want to try this picture again. I like the image, but my rendition didn’t come out as I had hoped.

I really like the thin beak of the original picture. I didn’t get the beak as thin as I would have liked. I used a lot of pins, but it was hard to keep the bias in place as I sewed and I am not sure why. The wobble also resulted in all of the straight lines ending up wobbly. This is because I didn’t have the Wonder tape called for in the directions (I have it now). I didn’t add fusible to my bias tape, which was an option I didn’t think about.

Still, I made something for the challenge. I was also expecting progress not perfection. WooHoo!

I was excited about this challenge, because I had been wanting to learn to make bias tape using bias tape makers. It might useful for embellishing or design purposes in the future. This was the perfect opportunity.

After cutting and sewing the bias, I fed the piece through using a pin and the device started making bias tape! I couldn’t believe it that the process worked. Once I got going, I found it incredibly useful to poke a pin into my pressing surface to hold the bias in place. As I reached the end of my pressing mat with the iron, I had to move the pin.

I was disappointed that the directions did not talk about type of fabric or any challenges that might occur. I found a couple of things that were challenging.

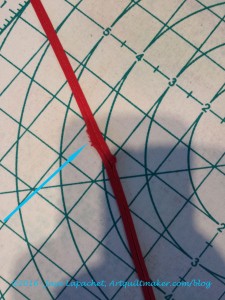

First, I used a Kona Solid for the red bias tape. As I have mentioned in the past there is a lot to like about Kona, but its loose weave is not a bonus. I cut my strips about 1/2″ wide and as I fed them through the bias tape maker to make 1/4″ bias, the seams got hung up on the device. The bias tape maker had a real problem going over them as I pulled the tape through. I ended up helping them with a stiletto, but the seams looked terrible once the tape was made, as you can see in the photo with the blue arrow. The photo is of completed bias tape. You can see that the line is not smooth and there is a marked bump in the tape. Yes, I pressed the seams flat and they are still not attractive. The seams are also already starting to fray.

I am thinking that the problem could have been the fabric, as mentioned, combined with the size of the bias tape I chose to make. I’ll have to experiment some more to see what works. Looser weave fabric might work just fine with a larger sized bias tape maker. I do think I might try this technique with Art Gallery Pure Elements Solids as they are thin and tightly woven. I am not sure if that line has a bright scarlet.

Second, there was no way of knowing how much bias tape could be made. There was no chart like a bias binding chart included with the directions. Would a bias binding chart used for binding a quilt work? I tried looking at one, but it don’t go down to a small enough width of tape. I now have about 500 yards of bias tape still to use, which is why I am not concerned about a do over.

Yes, I had to sew all of those tiny strips together, which was another ordeal in itself. I should have used the tube bias method.

Next, I used the 1/4″ bias tape maker. It worked like a charm, but is very small. I would recommend using a 1/2″ or 3/8″ bias tape maker on your first time out.

Fourth, the directions did not talk about using a Point Trimmer. A Point Trimmer helps you line up the edges of the bias tape to sew it together in a long string. You can use it for your binding strips as well if you don’t use the tube binding method. As an aside, if you don’t have Point Trimmer ruler, you really need to get one. I like the Judy Martin version because it helps you trim two types of triangles in one tool BUT there are other manufacturers who make them and almost any are good.

Fifth, these bias tape makers are not readily available. I went to three stores, checked Amazon, Fabric.com and some other places before I found a full selection at Beverly’s. The quilt stores didn’t have them. Amazon, etc had a few, but not all the sizes and not sold in sets. None of the online places could get them to me in a timely manner. I now have a set of them and won’t need to buy them again, but I was surprised. If I were Lucky Spools, I would have made a deal with some shop to sell kits of the bias tape makers and the Wonder Tape.

Sixth, there were very few instructions about pressing. The author of this ‘lesson’ did say to keep your fingers away from the hot iron, but not much else. I used a type of stiletto, which prevented me from burned fingers. It is two pronged, which gives me more ‘holding’ surface. I think I bought it at a booth at the county fair or PIQF where they sell every kind of scissor and small metal tool known to mankind.

There is more come on this technique as I will post about my next effort.

Learning is not a smooth process. I am not complaining about any of the above; I am just telling you my story. One lesson for me is to try different brands of solids. Kona is just so easy to find! I am glad I tried this technique and learned how to make bias tape with these devices.